WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How Much Does It Cost to Recycle Solar Panels in Australia?

July 3, 2025

July 3, 2025- FAQ

- Leave a message

- Chat online

With the rapid development of the solar energy industry, Australia is facing a growing demand for recycling retired solar panels. As one of the countries with the most widespread photovoltaic applications in the world, Australia generates tens of thousands of waste solar panels that need professional treatment every year. This article will analyze in detail the specific cost structure of recycling solar panels in Australia, including key cost factors such as raw material processing, equipment investment,operation and maintenance,and comprehensively analyze the various expenses in the recycling process.

Raw Material Cost

The raw material cost of solar panels is very low, about 2-3 Australian dollars per piece, and even recycling the raw materials can bring extra benefits. Compared with landfill disposal, governments at all levels in Australia encourage the adoption of environmentally sustainable solar recycling methods and even provide corresponding subsidy policies. For example, South Australia's "Zero Waste Program" provides additional support for compliant recyclers, while Victoria makes manufacturers bear the recycling costs through the extended producer responsibility system. Therefore, it is recommended that you understand local policies and find a stable source of used solar panels.

Raw material of solar material

Raw material of solar material

Equipment Cost

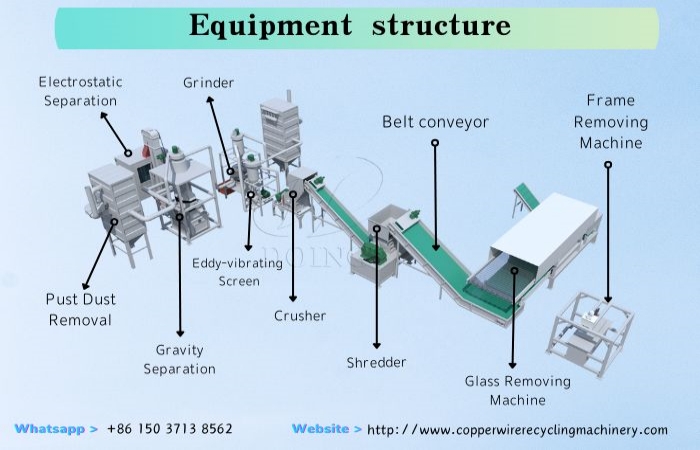

Establishing a complete solar panel recycling production line requires a fully integrated system including aluminum frame removal machines, glass separation units, conveyor systems, dual-shaft shredders, crushers, water-cooled grinding mills, vibrating screens, air separation systems, and separators, all equipped with pulse dust removal for environmental compliance. The price of solar panel recycling equipment fluctuates depending on the processing volume, production line configuration and supplier, and is approximately A$70,000-350,000. For a standard facility processing 50,000 panels annually, equipment depreciation averages AUD 2-4 per panel.

DOING’s solar panel recycling equipment adopts advanced multiple separation technology enhances valuable final products recovery rates by 30% compared to conventional methods, delivering higher long-term efficiency while maintaining cost-effectiveness through modular, energy-optimized designs that scale from small operations to high-volume recycling plants.

DOING solar panel recycling equipment

DOING solar panel recycling equipment

Daily Operating Costs

The daily operation of a photovoltaic panel recycling equipment involves multiple cost factors, with labor, energy consumption, equipment maintenance, and regulatory compliance forming the core expenses. Economies of scale play a crucial role, as large-scale plants can significantly reduce per-unit processing costs compared to smaller operations. The operational efficiency of the solar panel recycling process, equipment reliability, transportation expenses and local regulatory requirements all further influence the final operating cost structure.

Therefore, in general, the investment costs of developing solar panel recycling business in Australia include many aspects, which are related to the investment scale of the entire project. However, through DOING's equipment, we can recycle and extract high-value silicon, copper and other products, which have a wide market and high selling price, helping you quickly recover your investment.

Photovoltaic panel recycling equipment

Photovoltaic panel recycling equipment

If you need professional and reliable solar panel recycling equipment, or want to know more about recycling cost optimization solutions, please feel free to contact DOING's expert team. DOING provides customized recycling solutions across Australia to ensure that your waste solar panels are treated in an environmentally compliant manner while achieving the best economic benefits.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.