WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What machines are needed for making ecological charcoal?

June 24, 2025

June 24, 2025- Industry News

- Leave a message

- Chat online

As an environmentally friendly fuel, ecological charcoal plays an important role in agricultural improvement, energy utilization and environmental protection. If you are considering entering the field of eco-charcoal production, understanding the professional machine required is the first step to success.

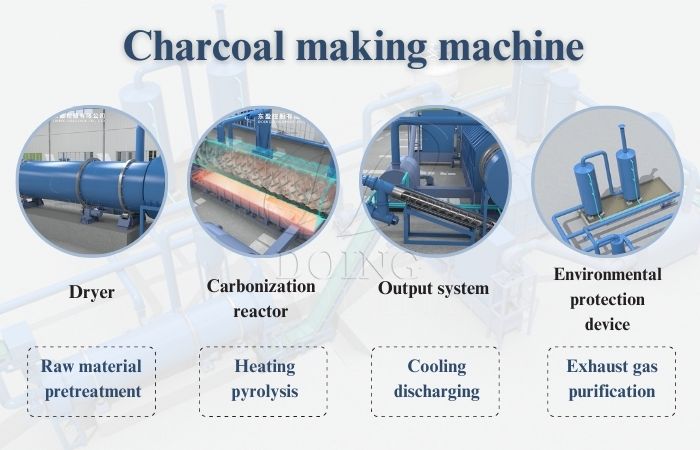

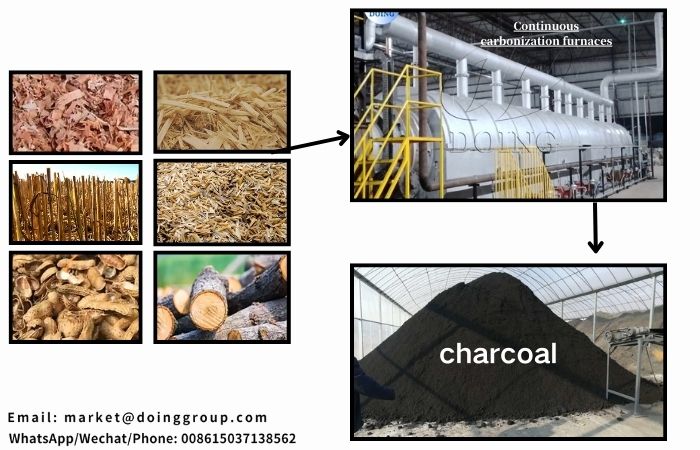

Several types of machine are usually needed to produce ecological charcoal. These include raw material preparation machine (such as crusher and dryer), carbonization machine (such as carbonization furnace or carbonization kiln), auxiliary equipment (such as conveyor, screening machine and packaging machine), and environmental protection machine (such as dust removal equipment and exhaust gas treatment facilities). The choice of specific equipment depends on the production scale, raw materials and process flow. The following will give you a detailed introduction to the machines usually required to make ecological charcoal.

Machines needed to make ecological charcoal

Machines needed to make ecological charcoal

Raw Material Processing Machine

The raw material processing link requires a crusher and a dryer. The crusher can crush raw materials such as wood and straw into uniform small pieces, while the dryer can effectively reduce the moisture content of the raw materials, thereby processing the biomass raw materials into a state suitable for carbonization. Generally, it is necessary to ensure that the raw material particle size is within 30 mm and the moisture content is below 15%, which is crucial for the subsequent carbonization efficiency.

DOING dryer for biomass raw material processing

DOING dryer for biomass raw material processing

Charcoal Carbonization Kiln

This machine is used in the carbonization process to convert raw materials such as wood, rice husks and other biomass into charcoal. This process is to heat under oxygen isolation conditions, so that the moisture and volatiles in the raw materials evaporate and decompose, and the wood fibers gradually carbonize, and finally form solid charcoal with high carbon content and high combustion value.

Charcoal carbonization kiln for making ecological charcoal

Charcoal carbonization kiln for making ecological charcoal

The carbonization link is the core of ecological charcoal production, which requires the use of professional carbonization kiln equipment. The charcoal carbonization kiln provided by DOING Company adopts a reasonable design, has good sealing performance, can achieve uniform temperature control, and ensure stable and efficient carbonization process. In addition, DOING charcoal carbonization kiln series includes a variety of specifications of processing capacity, which can handle various biomass materials to meet the production needs of different scales. Our machine is easy to operate, have reasonable maintenance costs, and are suitable for long-term continuous production.

Cooling System

The cooling system directly affects the quality and safety of finished charcoal. Reasonable cooling design can shorten the production cycle while ensuring the stable quality of ecological charcoal. In addition, the exhaust gas treatment device is also an essential environmental protection machine in modern ecological charcoal production. DOING charcoal carbonization kiln can effectively reduce the flue gas emissions in the production process by reasonably configuring dust removal and exhaust gas treatment equipment, ensuring the environmentally friendly production of ecological charcoal.

Charcoal cooling machine for high quality charcoal

Charcoal cooling machine for high quality charcoal

Auxiliary Equipment

In addition to the main production machine, some auxiliary equipment can also significantly improve production efficiency. Conveyors can reduce the burden of manual handling and improve the degree of automation of the production line. Packaging machine can quickly complete the packaging of finished products, which is convenient for subsequent storage and transportation.

Charcoal Making Briquetting Machine(Optional)

If there is a demand for different shapes of charcoal products, DOING can also provide different capacity charcoal briquetting machines. These equipment are used to press the carbonized ecological charcoal materials into various shapes of shaped charcoal (blocks, rods, granules) to meet the needs of different uses, thereby improving the combustion efficiency, transportation convenience and commercial value of charcoal.

Charcoal making briquetting machine

Charcoal making briquetting machine

These machines together constitute a comprehensive system for producing ecological charcoal. DOING not only provides the core charcoal carbonization kiln, but also can configure a complete ecological charcoal production line solution according to the actual needs of customers. From the initial raw material processing, carbonization to the final block making and packaging, there are corresponding equipment to choose from in each link.

When choosing ecological charcoal making machine, you need to consider many factors such as raw material type, expected output, site conditions, etc. We recommend that you first clarify your own needs and then consult professional technicians for customized suggestions. DOING company's technical team has rich experience and can provide you with full support from equipment selection to installation and commissioning.

If you want to know more technical details, please feel free to contact us. Our professional consultants will recommend the most suitable production solution based on your specific situation.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.