WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

DOING charcoal kiln: Advantages of efficient biomass carbonization

June 20, 2025

June 20, 2025- FAQ

- Leave a message

- Chat online

Charcoal has long been a vital fuel source, and its production largely depends on a crucial device known as the charcoal kiln. In this article, we will delve into the principles, the comparison of various types of charcoal kilns, and the remarkable advantages of the DOING charcoal kiln, a leading solution in the charcoal production industry.

How does a charcoal kiln work?

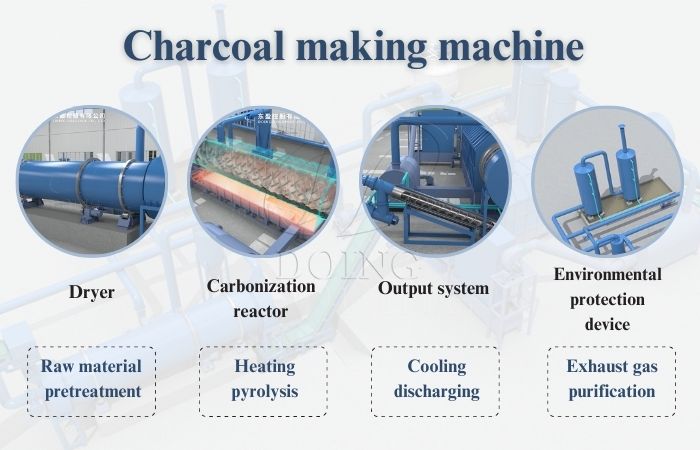

A charcoal kiln is a specialized container, usually made of materials such as bricks, clay or metal. Its main function is to decompose biomass into biochar, combustible gases and liquids through a high-temperature carbonization process in an oxygen-free environment. The operation of a charcoal kiln can be divided into four key stages:

DOING Charcoal kiln working process

DOING Charcoal kiln working process

1. Sealing

The charcoal kiln creates a sealed, oxygenfree chamber that holds the biomass and regulates airflow. This controlled environment is essential for efficient carbonization.

2. Heating

The biomass inside the kiln is ignited and carefully heated. The temperature is precisely controlled to dry the biomass, preparing it for carbonization.

3. Carbonization

As carbonization progresses, the airflow is gradually reduced. This causes the burning biomass to break down further, producing charcoal as well as gases and liquids that can be used as fuel.

4. Cooling and Collection

Once the carbonization process is complete, the charcoal is cooled to prevent spontaneous combustion. After cooling, the charcoal is carefully collected for various applications.

The comparison of types of Charcoal Kilns

Charcoal kilns come in various forms. Here are some of the most common types:

| Kiln Type | Features | Advantages | Disadvantages | Suitable for |

| Earth Kiln | Wood, soil, small opening | Simple, cheap | Low control, inefficient | Small-scale, traditional use |

| Brick Kiln | Brick, reusable | Durable | Limited control | Medium-scale use |

| Metal Kiln | Metal, good control | Efficient, durable, low maintenance | High cost | Modern production |

| Distillation Kiln | Combustion chamber, gas fuel | High efficiency | Complex, high cost, limited adaptability | Large-scale, funded projects |

Compared with the traditional charcoal kiln, DIONG charcoal kiln has the following advantages:

High production efficiency

The DOING continuous carbonization furnace adopts synchronous feeding and carbonization mode, which can achieve 24-hour uninterrupted production for 7 days, significantly improving production efficiency. In addition, the carbonization furnace is equipped with a PLC automated intelligent control system. Operators can easily manage the startup, operation and monitoring of the equipment through a user-friendly interface, thereby reducing operational complexity and labor requirements.

Energy saving and environmental protection

The combustible gas generated during the carbonization process can be recycled as fuel to heat the carbonization furnace, achieving self-sufficiency without the need to add additional fuel. Equipped with an environmental control system, it can effectively remove harmful gases generated during the carbonization process to ensure compliance with emission standards. There is no dust leakage or dust, which is an environmentally friendly choice.

Wide range of raw materials

Raw materails of DOING charcoal kiln

Raw materails of DOING charcoal kiln

DOING charcoal kilns can process a variety of biomass materials, including hardwood, softwood, bamboo, nut shells, corn cobs, straw, and even various sludge or waste, such as urban sludge, river sludge, kitchen waste, industrial waste and animal manure.

Flexible capacity options

The kiln offers a variety of capacities, such as 1 t/h, 2 t/h, 3 t/h, 5 t/h and above, and can be customized according to the specific needs of customers.

Excellent equipment performance

The kiln is made of high-quality materials, which is resistant to high temperatures and corrosion, and improves the stability and service life of the equipment.

Decoking device

For kilns that process materials that are prone to coking (such as tar, slag, etc.), a decoking device is installed on the inner wall of the kiln. This device can effectively remove existing coke and prevent the formation of new coke.

DOING charcoal kiln manufacturer

DOING charcoal kiln manufacturer

The DOING charcoal kiln represents a significant advancement in biomass carbonization technology. With its high efficiency, environmental sustainability, versatility, and superior performance, it offers a comprehensive solution for modern charcoal production. If you are interested in learning more or require a customized charcoal kiln solution, please feel free to contact us. We are here to provide you with a tailored DOING Charcoal Kiln plan to meet your specific needs.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.