WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How Does a Lithium Battery Recycling Plant Work?

August 1, 2025

August 1, 2025- FAQ

- Leave a message

- Chat online

With the rapid growth of electric vehicles and renewable energy storage, recycling lithium batteries has become crucial for both environmental protection and resource sustainability. A well-designed lithium battery recycling plant efficiently recovers valuable materials like lithium, cobalt, nickel, and copper while minimizing waste.

The following lithium battery recycling plant workflow demonstrates the efficient process designed by Henan Doing Company:

1.Collection and Safe Transportation

The lithium battery recycling plant workflow begins with careful collection and transportation. These batteries, sourced from electric vehicles, consumer electronics, and industrial storage systems, must be handled with strict safety protocols to prevent hazards. Proper sorting by battery type ensures optimal processing efficiency.

2.Discharge and Dismantling

Before recycling, batteries undergo a complete discharge to eliminate residual energy. Automated dismantling systems then separate battery packs into their core components—removing casings, wiring, and electronic circuits. This step prepares the batteries for mechanical processing while ensuring worker safety.

Lithium battery recycling workflow

Lithium battery recycling workflow

3.Mechanical Crushing and Separation

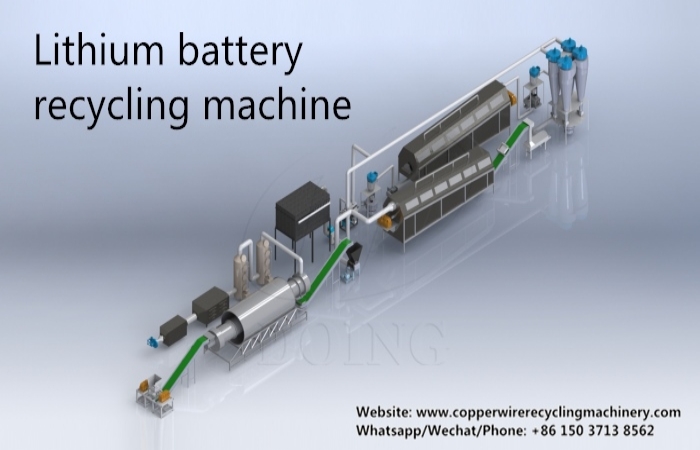

The heart of an efficient lithium battery recycling plant lies in its mechanical processing system. DOING’s advanced dry physical separation technology eliminates the need for chemical treatments, making the process more environmentally friendly. The system includes:

Shredding & Crushing: Through multi-layer crushing, better sorting effect can be achieved.

Magnetic Separation: Recovers iron and steel for reuse in the metal industry.

Screening & Gravity Separation: Isolates copper, aluminum, and plastics with high precision.

Black Mass Extraction: The remaining powder, rich in lithium, cobalt, and nickel, is collected for further refining.

This method ensures high recovery rates (up to 99%) while reducing energy consumption and pollution compared to traditional hydrometallurgical processes.

Doing lithium battery recycling machine

Doing lithium battery recycling machine

4.Pollution prevention and environmental protection control

Environmental controls are seamlessly incorporated throughout the entire recycling process. Modern lithium battery recycling plants like those equipped with DOING's technology prioritize sustainability through comprehensive protection measures. Advanced pulse dust removal and wastewater treatment systems operate continuously to meet strict environmental standards, while simultaneously enhancing metal recovery efficiency and minimizing ecological impact.

Raw materials separated from lithium batteries

Raw materials separated from lithium batteries

All in all,through this systematic recycling process - from safe collection and discharge to mechanical separation and environmental controls - modern lithium battery recycling plants achieve remarkable material recovery rates up to 99%. DOING's complete solutions implement this advanced dry physical separation technology throughout every stage, ensuring efficient recovery of lithium, cobalt, nickel and other valuable materials while meeting the highest environmental standards. The combination of multi-layer crushing, precision sorting technologies, and plant-wide pulse dust removal systems demonstrates how technical innovation can transform battery recycling into both an environmentally responsible and economically viable industrial process.

Contact DOING today to learn how our recycling systems can help your business turn end-of-life batteries into a sustainable revenue stream.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 1000kg/h Solar PV Panel Recycling Machine Shipped to India

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.