WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Which Industry Needs Rice Husk Charcoal?

December 16, 2025

December 16, 2025- FAQ

- Leave a message

- Chat online

Rice husks, a common agricultural waste, are produced in vast quantities globally each year. Using carbonization/pyrolysis technology, these rice husks can be efficiently converted into clean carbonaceous energy---charcoal with high calorific value and low ash content. Rice husk charcoal, also called rice husk biochar (RHB), has low production costs, continuously growing market demand, and a wide range of applications, thus attracting significant investment from enterprises and becoming a key focus of the charcoal prduction industry.

Here are the wide industrial applications of rice husk charcoal:

Agriculture and Horticulture

The agriculture sector is a primary consumer of rice husk charcoal, where it is used as a soil amendment. Farmers value it for improving soil structure, increasing water retention in sandy soils, and boosting nutrient availability. It acts as a stable carbon sink, enhancing soil health over the long term. In horticulture and greenhouse operations, it’s a key component in potting mixes and substrate blends, promoting stronger root development and plant resilience.

Rice husk charcoal for improving soil health

Rice husk charcoal for improving soil health

Metal Production and Foundries

In metallurgy, rice husk biochar serves as an efficient, renewable insulating cover material in foundries. It is used to maintain molten metal temperature and reduce heat loss during processing. Furthermore, due to its high silica content after carbonization, it finds application in steel production as a substitute for more expensive carburizers and slag conditioners, helping to manage impurities.

Water and Air Filtration

Activated rice husk charcoal is highly effective in filtration. Water treatment plants and home filter manufacturers use it to adsorb contaminants, odors, and organic impurities. Similarly, in industrial air purification systems, it helps capture volatile organic compounds and odors, providing a sustainable and efficient filtering medium compared to some non-renewable alternatives.

Highly efficient filtration of activated rice husk charcoal

Highly efficient filtration of activated rice husk charcoal

Building and Construction Materials

The construction industry utilizes rice husk charcoal as a lightweight additive in bricks and concrete mixes. It enhances thermal insulation properties and reduces the overall weight of building materials. Some manufacturers also incorporate it into low-cost, sustainable insulation panels, leveraging its porosity and stability.

Livestock and Animal Husbandry

Farmers add rice husk charcoal to animal feed as a dietary supplement for livestock, poultry, and even aquaculture. It is known to aid digestion, improve gut health, and absorb toxins in feed. Additionally, it’s used as an odor-absorbing bedding material in poultry houses and stables, improving overall farm hygiene and ammonia control.

Rice husk charcoal for livestock feed

Rice husk charcoal for livestock feed

Renewable Energy and Fuel

Processed rice husk biochar can be compressed into biomass briquettes, serving as a high-calorific, low-smoke solid fuel for heating and cooking. This offers a cleaner-burning alternative to raw wood or coal in both residential and certain industrial boiler applications, supporting the shift toward sustainable fuel sources.

The increasing demand for rice husk charcoal across various industries has made its production a viable business opportunity. Industry forecasts predict that the biomass energy market will grow at an average annual rate of 5%–10%, especially in the Asian, African, and European markets. Furthermore, numerous countries globally offer policy support for biomass energy projects, with some regions providing substantial government subsidies, tax breaks, and carbon credit incentives, offering investors additional returns. These factors help companies unlock more profit channels by investing in rice husk charcoal production businesses.

Rice husk biochar production business

Rice husk biochar production business

If you are considering investing in this related business, it is important to note that the key to success lies in the efficient production of stable, high-quality biochar. Reliable biochar production equipment is crucial for achieving this goal.

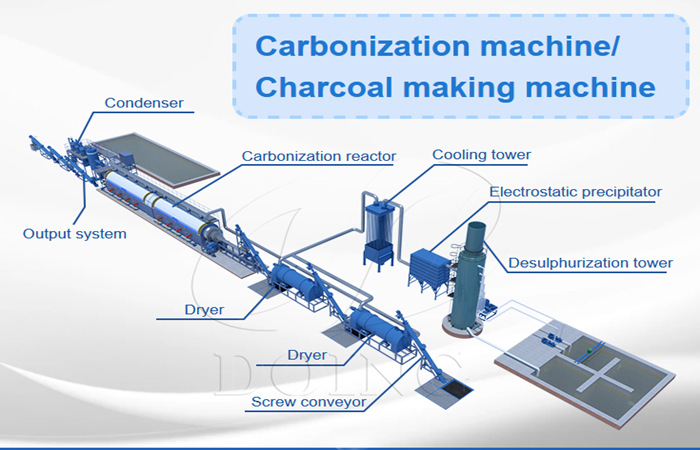

When considering production, selecting the right rice husk charcoal making machine is a fundamental step. DOING's biochar production equipment is designed for practical applications, ensuring stable operation. Precise temperature control ensures the uniformity and high quality of the rice husk charcoal, making it suitable for the industries that need rice husk charcoal; efficient sealing design balances safety and energy efficiency; and automated processing from feed to discharge simplifies operation. Our systems also integrate flue gas purification, meeting environmental standards, and recycle combustible gases for furnace heating, significantly reducing fuel costs. We offer equipment of various sizes, from small intermittent units to fully continuous systems with a daily capacity exceeding 20 tons, helping you find practical solutions to meet your project objectives.

Henan DOING rice husk biochar production equipment

Henan DOING rice husk biochar production equipment

If you are exploring opportunities in rice husk charcoal production, we are here to help. Contact us to discuss how our biochar production equipment can fit your specific plans.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.