WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Can you make money recycling lithium batteries?

June 26, 2025

June 26, 2025- FAQ

- Leave a message

- Chat online

In recent years, the popularity of electric vehicles, electronic products and energy storage systems has led to a surge in demand for lithium batteries. But at the same time, the number of discarded lithium batteries has also increased year by year. With the strict implementation of environmental regulations and the increasing shortage of battery resources, the importance of lithium battery recycling has become increasingly apparent.

Environmental and economic value of lithium battery recycling

Environmental and economic value of lithium battery recycling

Recycling scrap lithium batteries can not only reduce pollution to the environment, but also extract valuable metals such as lithium, cobalt, nickel, etc., which have important applications in the new energy industry. Therefore, lithium battery recycling not only has environmental value, but also considerable economic benefits.

The profitability of lithium battery recycling mainly comes from the following aspects:

1. Recycling valuable materials

Waste lithium batteries contain a variety of precious metals, such as nickel, cobalt, lithium, copper and aluminum, which are expensive in the market, especially cobalt and lithium. After professional recycling equipment extracts valuable metals, they can be sold directly to related manufacturing companies, and these recycled materials can often obtain considerable profits.

2. Reduce the cost of purchasing raw materials

Since the manufacture of lithium batteries relies on a large amount of metal raw materials, recycling lithium batteries can effectively reduce dependence on raw materials and reduce production costs. This is also an important reason why many companies have begun to invest in lithium battery recycling.

Recycling lithium batteries valuable materials

Recycling lithium batteries valuable materials

3. Second-use opportunities

Some retired lithium batteries still retain 70%-80% of their initial capacity. After testing and reorganization, they can be used in areas such as energy storage with lower requirements, thereby extending their service life and creating secondary value.

4. Environmental policy incentives

With the advancement of environmental protection policies, countries are strengthening the management of waste battery recycling and encouraging the establishment of a sound recycling system. Therefore, many countries and regions provide subsidies and preferential policies for lithium battery recycling. Enterprises can enjoy financial support from policies by recycling lithium batteries in compliance with regulations.

Lithium battery recycling production line

Lithium battery recycling production line

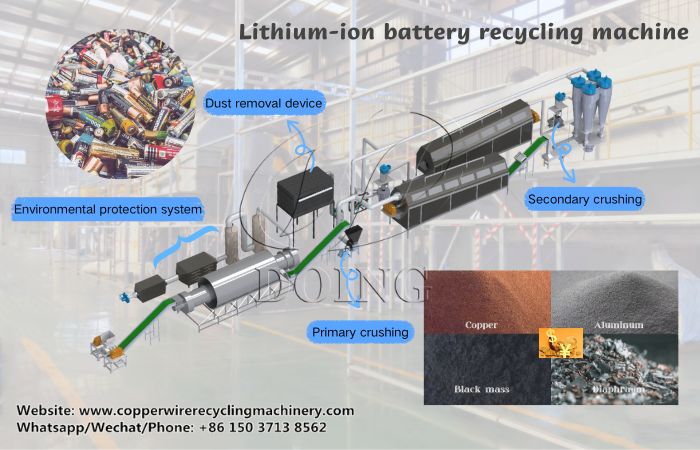

It is worth noting that to achieve these profit points, professional lithium battery recycling equipment is needed as support. The lithium battery recycling machine series provided by DOING covers all aspects from battery disassembly, material separation to hazardous substance treatment. Through automated and intelligent lithium battery recycling production lines, recycling companies can improve efficiency and safety and reduce costs.

If you are considering starting a lithium battery recycling business, the following suggestions may be helpful to you:

① Fully understand local policies and market conditions and do a good job of preliminary research

Pay attention to the relevant laws and regulations of the national and local governments on lithium battery recycling, especially environmental protection policies and subsidies or incentives for battery recycling. In addition, market demand also needs to be fully investigated and analyzed to analyze the potential customer groups for battery recycling, including changes in demand in industries such as electric vehicles, power tools, and consumer electronics.

② Assess your own financial strength and choose the appropriate machine investment scale

We can flexibly configure according to the actual needs of customers. For companies that have just entered the field of lithium battery recycling, we recommend starting with a small production line and gradually upgrading the equipment as the business expands. Our technical team provides full consulting services to help customers choose the most suitable equipment solution.

③ Establish a stable source channel for waste lithium batteries and a sales network for recycled materials

Different types of lithium battery raw materials

Different types of lithium battery raw materials

For lithium batteries of different specifications, DOING lithium battery recycling machine can achieve safe disassembly and effective sorting, and improve the recovery rate of valuable materials. When collecting raw materials, you can rest assured to purchase lithium-ion battery materials such as mobile phone lithium battery, EV lithium battery and soft-pack lithium battery, except for nickel-cadmium battery, lead-acid battery and mercury-containing battery. As for product sales channels, it is recommended that you actively communicate with the corresponding buyers and purchase volumes, which will help you better determine the scale of lithium battery recycling and sell the products at a more expensive price.

④ Pay attention to environmental compliance and avoid risks caused by illegal operations

DOING lithium battery recycling production line adopts closed processing to avoid leakage of harmful gases. At the same time, it is equipped with an exhaust gas treatment system to ensure that the recycling process is harmless to the environment and meets environmental protection standards.

In short, lithium battery recycling does have profit potential, but success depends on business strategy, equipment level and market grasp ability. Our company not only provides lithium battery recycling machine, but also shares industry experience to help customers avoid detours. If you have any questions about lithium battery recycling business or related equipment, please feel free to contact us. Our professional team will provide objective and practical suggestions and solutions based on your specific situation.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.