WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

What is a PCB e waste recycling machine and how does it work?

May 16, 2023

May 16, 2023- FAQ

- Leave a message

- Chat online

What is a PCB e-waste recycling machine?

PCB e waste recycling machine

PCB e waste recycling machine

PCB e-waste recycling machine is a machine, which is designed to recycle PCBs, such as computer boards, mobile boards, TV boards, copper clad laminate, etc. This machine can extract the precious metals and non-metals from waste circuit boards to reuse these metals. Besides, it can destroy the data on the circuit and protect our privacy.

How does PCB e waste recycling machine work?

The PCB e waste recycling machine can separate precious metal and resin & fiber from scrap PCBs in a physical way, by crushing and separating. The working process is as follows:

PCB dismantling machine

PCB dismantling machine

-If there are electronic components on your waste PCBs, the first step of PCB e waste recycling machine is to remove the electronic components. (Of course, if you don't want to remove the electronic components, it can be skipped). PCB dismantling machine is used to dismantle the electronic components from waste PCBs, uses the property that metal tin will melt at high temperature and the friction between the circuit boards.

-A shredder would be necessary to preprocess the waste PCBs, if the waste PCBs you collected are particularly big or thick, or your processing capacity is 500kg/h or higher.

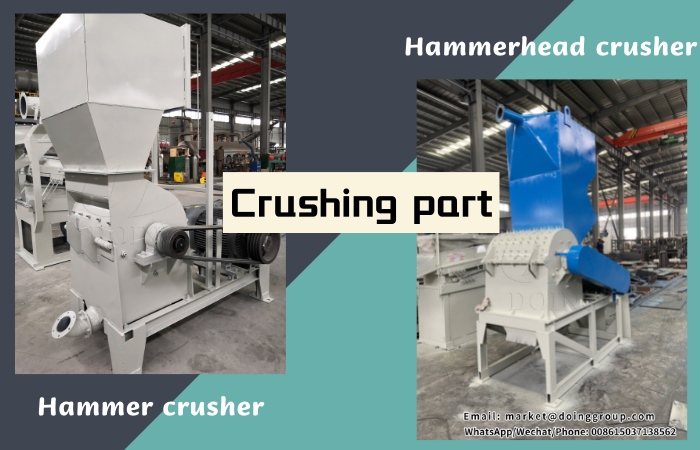

Two crushers

Two crushers

-Then the processed PCB boards will be crushed into small particles by two crushers. The first crusher is hammerhead crusher, which can crush waste PCBs into 8-10mm particles, and then the crushed particles will be further broken into finer particles of 2-3mm by the second hammer crusher.

-Between the two crushers, there is a magnetic separator on belt conveyor. It is aimed to remove the iron to promote the separating rate.

-Next, the finer particles will be sent into the eddy-vibrating screen. Inside the eddy-vibrating screen, there is a screen with 20mesh, which is used to control the size of particles. The bigger particles will be blocked on the screen, and then sent back to the second crusher to continue crushing until it can pass through the screen.

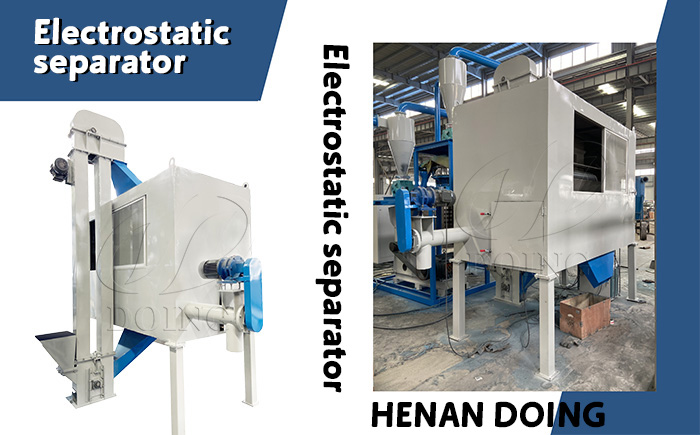

Electrostatic separator

Electrostatic separator

-Last, there are two separation: air separation and electrostatic separation. Air separator will separate the metals and resin fibers according to their different gravity under the wind force and vibration. However, due to multiple crushing, the weight of some metals may be similar to the weight of the resin fibers, resulting in a slight metal content in the resin fibers. These metals and resin fibers will be sent into electrostatic separator to further separating according to their different conductivity. The separating rate can reach to 99%.

The following working video can help you to get a better understanding of working process of PCB e waste recycling machine.

-During the whole process, the cyclone and pulse dust collector will capture the dust with the collecting rate of 99.5% to make your site clean. Moreover, it uses no water, fire or chemicals, it is an environmental friendly machine.

Founded in 2011, Doing Group has 12 years of manufacturing experience. So if you are interested in PCB e waste recycling machine, please contact Doing Group, and you will get quality machines and processional service from Doing Group.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.