WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to set up a solar panel recycling plant in India?

December 25, 2025

December 25, 2025- Industry News

- Leave a message

- Chat online

According to a 2021 study by the National Solar Energy Federation of India (NSEFI), the cumulative PV waste volume is projected to reach nearly 1.8 million tonnes by 2030, highlighting an urgent need for dedicated recycling infrastructure. Establishing a processing facility is now a critical step to address this growing waste stream, recover valuable materials like silicon, silver, copper, and glass, and support a circular economy within the renewable energy sector. Here is a practical overview of the key steps involved in setting up a solar panel recycling plant in India.

Recycling waste solar panels in India

Recycling waste solar panels in India

1. Market Research and Planning

Effective market research is fundamental to the construction of solar panel recycling plants in India. This includes analyzing the quantity of waste panels, understanding their material composition, and finding stable buyers for recycled materials such as aluminum, glass, and copper. Furthermore, local regulations must be reviewed, including e-waste management regulations and environmental compliance requirements. The plant size and target recycling rate must be determined, ensuring compliance with India's policy framework. The meticulous planning at this stage will help in the subsequent implementation of Indian solar panel recycling plant construction solution.

2. Site Selection and Layout Optimization

Plant site selection must consider logistics, infrastructure, and scalability. Priority should be given to locations with reliable three-phase power, and convenient road connections to recycling networks and buyers of recycled materials. A key factor is matching the plant area to planned capacity: higher daily processing volumes not only require larger-scale solar panel recycling equipment but also sufficient space for receiving, storing, sorting, and temporarily storing outgoing materials. Typically, a small production line with a daily processing capacity of 1-5 tons requires approximately 800 to 1,500 square meters of plant space; while medium to large-scale lines may require over 2,000 square meters. A well-planned layout, clearly separating the processes from receiving, pre-processing, sorting to outgoing storage, is crucial for ensuring operational efficiency, production safety, and future expansion, which will help you successfully establish a solar panel recycling plant in India.

Photovoltaic panel recycling plant land size

Photovoltaic panel recycling plant land size

3. Equipment Procurement and Installation

Selecting robust solar panel recycling equipment capable of processing the types of panels common in India is crucial. The system should efficiently separate aluminum, glass, silicon, and copper while operating reliably under local climatic conditions. Professional installation and calibration are needed to ensure the equipment meets its stated recovery rates and operates safely. For example, DOING's dry physical separation system can be configured according to different throughput (e.g., 500-2000 kg/h), employs an automated system controlled by PLC, and is designed and tailored to the operating environment in India, enhancing cooling and dust prevention capabilities.

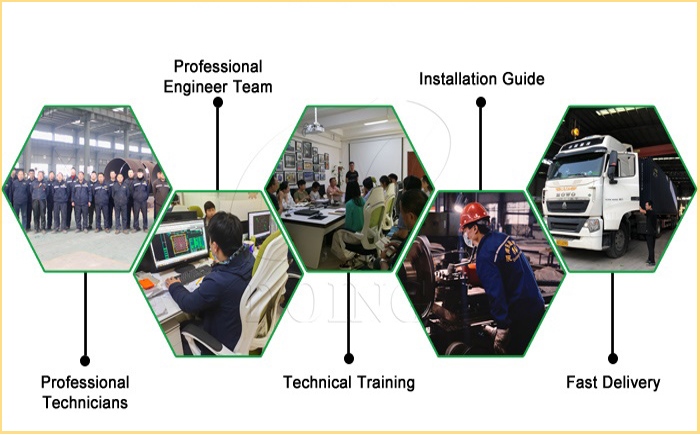

4. Personnel Training and Technical Support

Setting up a solar panel recycling plant also requires trained personnel responsible for equipment operation, maintenance, quality control, and safety management. A structured training program ensures the team can handle daily operations and basic troubleshooting. Reliable technical support minimizes downtime and maintains plant productivity. DOING provides comprehensive training and ongoing technical support to ensure your plant runs smoothly.

DOING professional technical training and installation guide

DOING professional technical training and installation guide

5. Environmental Approval and Compliance

setting up a solar panel recycling plant in India requires obtaining the necessary permits from the state pollution control commission and other relevant authorities. This includes submitting a detailed project report, an environmental management plan, and ensuring the plant complies with all applicable air, water, and waste treatment standards. A clear compliance roadmap avoids legal delays and supports sustainable operation. DOING's experience in project documentation and system design can help your plant meet regulatory requirements.

The most important factor in establishing a solar panel recycling plant in India is having high-performance solar panel recycling equipment, as this directly impacts the stability and profitability of your project. DOING's solar panel recycling systems are designed with practicality and operational reliability in mind. The entire process utilizes dry physical separation, resulting in zero wastewater and exhaust emissions, meeting international environmental standards. Through precise design, the recycling rate of aluminum frames, glass, silicon materials, and plastics reaches up to 98%, significantly reducing resource waste. We also offer customized services from single units to complete production lines to meet diverse customer needs.

Henan DOING solar panel recycling production line

Henan DOING solar panel recycling production line

If you are evaluating the steps to set up a solar panel recycling plant in India, Henan DOING Company can provide detailed equipment specifications and project insights based on our practical experience. Please contact us to discuss your specific requirements for an Indian solar panel recycling plant construction solution.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.