WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Process Workflow and Equipment for Lithium Battery Recycling

December 9, 2025

December 9, 2025- Industry News

- Leave a message

- Chat online

Standardized lithium battery recycling not only achieves resource recycling but also has positive implications for environmental protection. This article systematically introduces the lithium battery recycling process and explains the equipment required for key stages, hoping to provide a reference for investors in the battery recycling business.

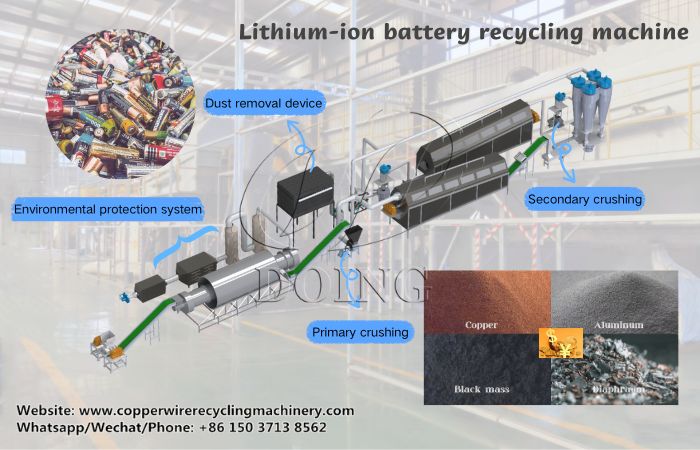

The lithium battery recycling workflow generally includes pretreatment, crushing, and sorting stages, each requiring corresponding equipment and technology.

1. Pretreatment Stage

Waste lithium batteries first need to undergo safe discharge treatment to remove residual charge and eliminate the risk of short circuits, ensuring operational safety. This step is crucial for safety and subsequent processing efficiency. Common lithium battery discharge methods include using salt water or specialized discharge chambers.

2. Crushing and Grinding Stage-Lithium battery dismantling crusher&Lithium battery grinding machine

The lithium battery casing is disassembled to expose the internal materials. Then, specialized crushing and grinding machines are used to break the battery components into small particles, preparing for material separation. The crushed battery materials undergo screening and magnetic separation to initially separate different components such as the casing, diaphragm, and electrode materials.

Lithium battery dismantling crushing process and equipment

Lithium battery dismantling crushing process and equipment

3. Material Sorting Stage-Lithium battery components screen separator&Airflow sorting machine

This stage aims to further separate valuable materials from the lithium battery. Physical sorting methods, such as airflow separation and vibrating sieving, are used to separate precious metals (copper, aluminum) and black mass (containing lithium, cobalt, nickel) and other impurities. Finally, the sorted materials can be refined to meet industry purity standards for use in the production of new batteries.

A complete lithium battery recycling production line requires the coordinated operation of multiple types of equipment. DOING can provide a variety of equipment, from battery pretreatment to material recycling. In particular, its lithium battery crushing and sorting machine demonstrates significant advantages: employing multi-stage crushing and sorting, through magnetic separation, precision screening, and airflow separation, it achieves a material recovery rate of over 98%, extracting high-purity recyclables that can be directly reintegrated into the manufacturing supply chain.

DOING lithium battery crushing, sorting and recycling production line

DOING lithium battery crushing, sorting and recycling production line

Furthermore, DOING's lithium battery recycling equipment optimizes the entire battery recycling workflow. Its PLC-controlled automated system covers the entire process from pretreatment to sorting, requiring only 1-2 operators for 24/7 continuous operation. This not only reduces labor costs but also minimizes human error, ensuring stable performance.

We also pay attention to the safety and environmental protection indicators of our equipment, striving to meet environmental management requirements while ensuring production. Safety and environmental compliance are built into every design. The fully enclosed processing system is equipped with advanced dust removal and exhaust gas treatment technologies to effectively prevent secondary pollution and comply with international standards like the EU Battery Directive and ISO 14001 certification.

DOING lithium battery recycling exhaust gas treatment machine

DOING lithium battery recycling exhaust gas treatment machine

A stable recycling workflow and reliable equipment are key to profitable lithium battery recycling. With decades of experience in manufacturing waste recycling equipment, DOING provides end-to-end support, including consulting, workflow design, equipment installation, operation training, and after-sales maintenance. Contact us now! We offer flexible capacity from 500 kg/hour to 2000 kg/hour and can provide customized solutions based on the scale of your lithium battery recycling business.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.