WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to set up a lithium-ion battery recycling production line in India

January 18, 2024

January 18, 2024- Industry News

- Leave a message

- Chat online

Considering the strong development of electric vehicles in India and the subsequent increase in battery waste, the lithium battery recycling business in India is set to boom. Setting up a lithium-ion battery recycling line in India involves several complex steps that require careful planning, investment and compliance with regulations. Here is a comprehensive outline of the steps and considerations entailed in setting up a lithium-ion battery recycling production line.

1.Preliminary Assessment

Market Analysis

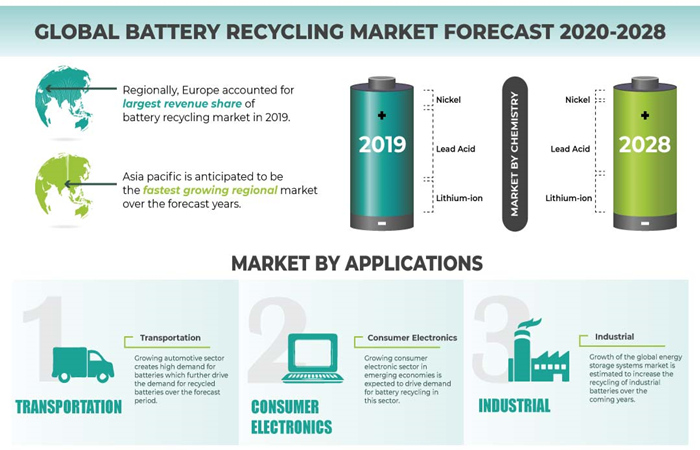

As a first step, conduct a comprehensive market analysis. India's EV market is burgeoning, and with it, the demand for battery recycling is increasing. The assessment should quantify the amount of battery waste that can be sourced and identify potential buyers for recycled materials.

Market analysis

Market analysis

Regulatory Compliance

Familiarize yourself with the Indian government's regulations regarding waste management, recycling, and hazardous materials handling. Compliance with the Ministry of Environment, Forest and Climate Change (MoEFCC) and Central Pollution Control Board (CPCB) guidelines is mandatory.

Location Selection

Choose a strategic location for your facility, considering proximity to battery collection centers, availability of electricity and water, logistics accessibility, and environmental impact. An industrial zone close to major EV markets can be ideal.

2.Technical Setup

Plant Design

Design a facility that adheres to safety and environmental standards. It should incorporate sections for battery disassembly, shredding, separation, extraction, and purification of materials, as well as waste treatment systems.

Plan design

Plan design

Equipment procurement

Equip the plant with state-of-the-art machinery for the recycling process. It is very important to choose a lithium battery recycling machine with advanced technology, high efficiency and low energy consumption to facilitate the development of lithium battery recycling business.

Lithium battery recycling machine

Lithium battery recycling machine

Henan Doing has more than thirteen years of professional experience, specializing in waste recycling machinery, and we have own high qualified engineer team. Our lithium battery recycling machine adopts advanced technology of crushing and separation system. After crushed separately, then copper aluminum and powder of positive and negative plate will be separated in the separation system with high purity output.

Final products

Final products

3.Financial Aspects

Capital Investment

Secure funding for the project through a mix of debt, equity, and grants. India's National Mission on Transformative Mobility and Battery Storage can be a potential source for financial aid.

Cost-Benefit Analysis

Perform a thorough cost-benefit analysis to project the facility's profitability. Include the costs of raw material acquisition, operations, labor, maintenance, and transportation, as well as the revenue from selling recycled materials and byproducts.

Cost benefit analysis

Cost benefit analysis

Incentives and Subsidies

Explore incentives offered by the Indian government for recycling businesses and green initiatives. These may include tax reliefs, subsidies, or concessional finance rates.

As a sunrise industry, lithium battery recycling business will continue to maintain strong growth momentum. Our lithium battery recycling production line can maximize your profits by increasing efficiency and minimizing waste. If you are interested, please feel free to contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.