WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Why is there such a high demand for charcoal?

October 16, 2025

October 16, 2025- Industry News

- Leave a message

- Chat online

As a sustainable resource, charcoal is increasingly used in a variety of fields, and market demand is steadily increasing. This trend is driven by multiple factors, including shifts in energy mix and the diversification of people's lifestyles.

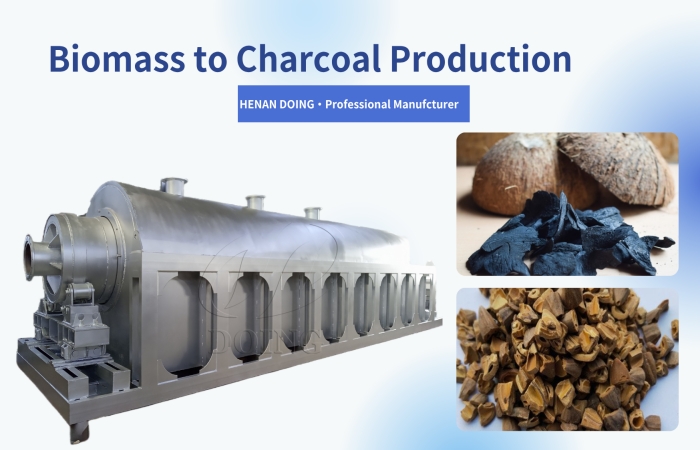

First, the charcoal manufacturing process offers significant environmental advantages compared to other energy products. Because charcoal is produced by carbonizing waste biomass, such as wood and fruit shells, it does not rely on fossil fuels, reducing environmental pollution. Furthermore, with stricter global environmental regulations, charcoal, as a relatively clean solid fuel, is increasingly being chosen by more and more industries and individuals as an alternative energy source, driving continued growth in demand.

Biomass carbonization to charcoal production process

Biomass carbonization to charcoal production process

Second, in regions like Nigeria, Ghana, Thailand, and Vietnam, charcoal remains an important domestic fuel, particularly in outdoor activities and the catering industry, where it is popular for its ease of use and stable combustion. As living standards improve, outdoor activities like barbecuing and camping are becoming increasingly popular, driving demand for charcoal.

Besides, charcoal has a wide range of uses, extending far beyond home barbecues. For example:

① In the industrial sector, charcoal is often used in metal smelting, especially in small-scale production, where its high-temperature combustion properties are used to produce high-quality steel and other metal materials.

② Charcoal's agricultural applications are also gaining increasing attention. In soil improvement, charcoal can help improve soil fertility and regulate soil structure, thereby promoting crop growth and supporting sustainable agriculture.

③ Charcoal is also widely used in environmental projects such as water treatment and air purification, where its adsorption properties provide a viable solution for environmental remediation.

Biomass produced charcoal applications

Biomass produced charcoal applications

As a renewable biomass energy source, charcoal has a low production cost, making it increasingly popular in the context of carbon neutrality. Many companies choose charcoal as a fuel because it is more economical than traditional coal and other energy sources. Furthermore, charcoal is relatively easy to store and transport, contributing to its continued growth in global demand.

With the increasing demand for charcoal, manufacturers need more efficient equipment to meet market demand. Choosing the right charcoal production machine can not only increase production but also effectively reduce operating costs.

Advantages of DOING charcoal making machine

Fast carbonization technology: Through an optimized furnace structure and heat circulation system, we maximize thermal energy utilization, significantly reducing the time required for carbonization. This means more charcoal can be produced in a shorter time.

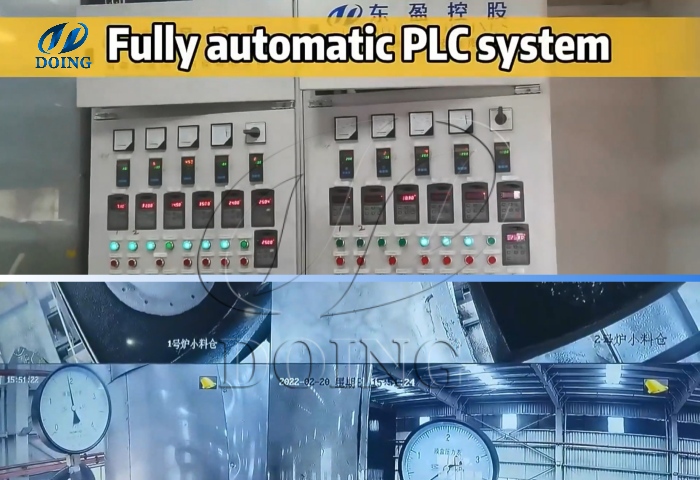

Automated control system: The integrated PLC intelligent control system precisely controls key parameters such as temperature and feed rate. This not only reduces manual operation complexity and errors, but also ensures consistent quality from batch to batch. Furthermore, the highly automated and consistent production process typically requires only one or two employees to monitor the entire production process, saving significant labor costs.

DOING charcoal making machine PLC intelligent control system

DOING charcoal making machine PLC intelligent control system

Self-generated gas recycling: The combustible gas generated during the carbonization process of our charcoal making machine is collected, purified, and returned to the combustion chamber as a supplemental heat source. This self-sufficient energy system significantly reduces your energy costs.

Wide raw material adaptability and flexible procurement costs: Our equipment can accommodate a variety of raw materials, including sawdust, rice husks, palm shells, straw, and other agricultural and forestry waste. You can choose the most readily available and affordable raw materials for production based on local conditions, significantly reducing raw material procurement costs.

Various biomass raw materials for carbonization charcoal production

Various biomass raw materials for carbonization charcoal production

With the gradual integration of global markets, demand for charcoal is no longer limited to traditional consumer markets. In developing countries, particularly due to unstable energy supplies, charcoal has become a vital fuel source. Coupled with the gradual strengthening of environmental protection policies in these countries, charcoal as a green and environmentally friendly alternative energy source is gaining increasing attention and application.

To better meet the demands of the global market, manufacturers require more efficient and environmentally friendly charcoal machine. DOING is committed to providing customized charcoal making machine solutions to customers worldwide, helping them gain an advantage in the fiercely competitive market. Welcome to leave a message to contact us!

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.