WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Sustainable Scrap Solar Panel Management: Unlocking Profit Potential with Advanced Sorting Technology

September 30, 2025

September 30, 2025- Industry News

- Leave a message

- Chat online

With the rapid development of the solar industry, previously installed photovoltaic panels are gradually reaching end-of-life. Sustainable management of scrap solar panels has become a critical issue for the industry. By applying advanced sorting technologies, recycling waste solar panels can not only reduce negative environmental impacts but also unlock potential economic profits.

Advanced Sorting Technology: Unlocking Hidden Wealth

The main components of solar panels, such as silicon, glass, and metals, are all recyclable resources. Recycling scrap photovoltaic panels goes beyond fulfilling environmental responsibility; it is a precise form of "urban mining." Advanced sorting technologies enable high-purity separation of glass, metals, silicon, and plastics, maximizing the economic value of each component.

①High-purity glass (approximately 65-75%): Recycled glass no longer needs to be cheaply disposed of as construction waste. After precise sorting to remove impurities, this high-purity glass can be directly recycled into new solar panels or used in industries such as fiberglass and thermal insulation, significantly increasing its added value.

High-purity glass from recycled scrap solar panels

High-purity glass from recycled scrap solar panels

②Precious metals (approximately the core of the value): This is the primary source of profit. Each standard solar panel contains approximately 10% aluminum (for the frame, which can be directly remelted), 2-3% copper (for the conductors), and, crucially, silver. Advanced sorting and extraction technologies ensure the efficient recovery of these precious metals, directly matching international raw material market prices and generating substantial returns.

③Silicon (approximately 5-10%): As the core of semiconductors, silicon wafers themselves possess significant value. Sorting technology allows for the recovery of high-purity silicon for reuse in the solar energy or electronics industries, creating a more profitable alternative to landfill or downcycling.

Solar panel crushing and sorting products

Solar panel crushing and sorting products

④Plastics and other components: Plastic components such as EVA (ethylene-vinyl acetate copolymer) can also be separated and converted into pellets for use in the production of low-demand plastic products, achieving full resource utilization.

The recycling market for scrap solar panels is maturing, and equipment equipped with advanced sorting technology can help companies better capture this market's potential. By recovering high-value raw materials, companies can not only reduce production costs but also generate revenue through secondary sales of recycled materials. Furthermore, the proper handling of used solar panels enhances a company's social responsibility image and earns customer trust.

DOING Company Expertise: Turning Scrap Solar Panels into Profit

As a leader in waste recycling solutions, Henan DOING Company provides:

Efficient Sorting Technology: DOING's solar panel recycling machine utilizes advanced physical sorting technology to efficiently and accurately separate the different materials in the solar panels, enabling efficient recycling.

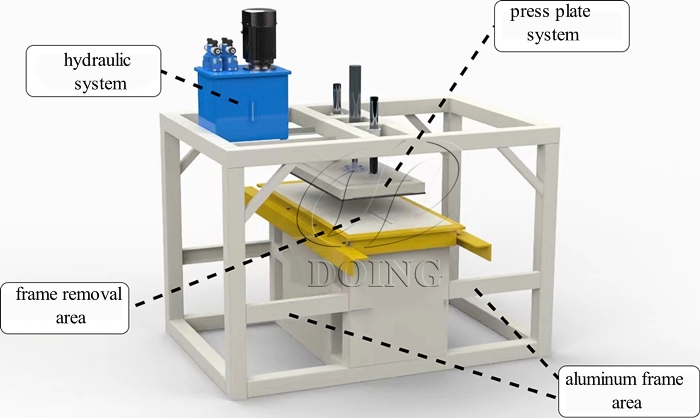

Multi-functional frame remover: Suitable for disassembling waste solar panels of various sizes, the aluminum frames can be directly recycled, with a recovery rate of nearly 100%.

Solar panel aluminum frame removal machine

Solar panel aluminum frame removal machine

Specialized crusher: Further crushes photovoltaic PV solar panels while preventing excessive glass pulverization.

Multi-stage sorting equipment: Using vibrating screens, electrostatic separation, and air separation, materials such as glass, silicon, and copper metal extracted from solar panels are separated based on physical properties such as density and conductivity.

Negative pressure vacuum system: Dust is collected during the crushing process (with a collection rate exceeding 98%) to prevent environmental contamination.

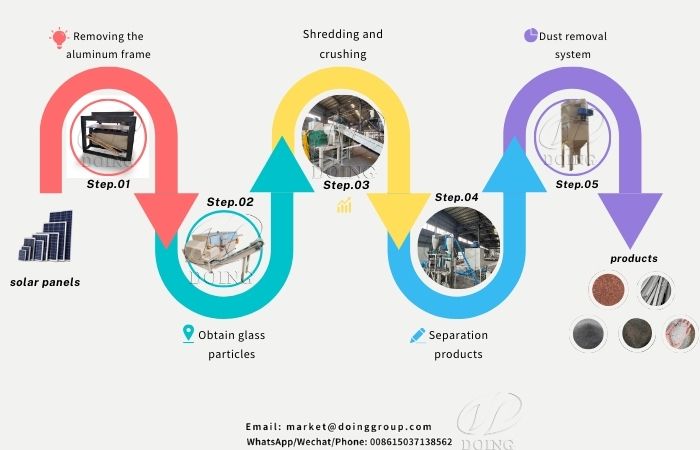

Fully Automated Recycling Process: Utilizing intelligent mechanical equipment, it automatically identifies and separates silicon, glass, and metal components, significantly improving recycling efficiency and resource utilization.

Fully automated solar panel recycling process

Fully automated solar panel recycling process

This sorting technology not only increases recycling rates but also minimizes manual errors and safety risks. For solar panel manufacturers and recyclers, this means lower operating costs and higher profit margins. We also prioritize environmental protection, using specialized equipment to effectively control and treat the dust and exhaust generated during the recycling process, contributing to the sustainable management of scrap solar panels.

Faced with the growing demand for scrap solar panel processing, investing in advanced sorting technology and equipment is a wise choice. Our company is committed to providing efficient solar panel recycling solutions, helping customers achieve both environmental and economic benefits. If you would like to learn more about solar panel recycling machine or sorting technology, please contact us to discuss how to unleash your profit potential through advanced solar panel recycling technology.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.