WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Why do we need to separate and recycle aluminum-plastic composite materials? What methods can be used?

January 30, 2024

January 30, 2024- FAQ

- Leave a message

- Chat online

As a relatively practical material, aluminum-plastic composite material provides a lot of convenience to our daily lives. By recycling aluminum-plastic composite materials, waste that might otherwise be discarded can be transformed into new raw materials that can be produced again. The process of recycling aluminum and plastics is less energy-intensive than the huge energy consumption required to mine, refine primary aluminum and manufacture plastics.

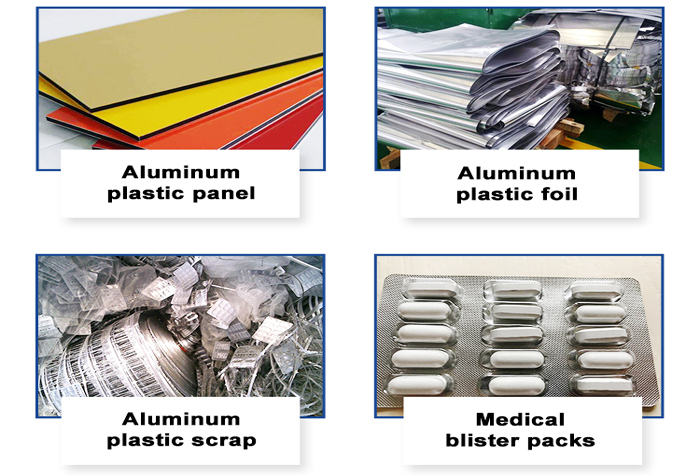

Aluminum-plastic composite materials

Aluminum-plastic composite materials

After understanding that aluminum-plastic recycling is an important task that takes into account both economic and environmental benefits, more efficient and environmentally friendly recycling technologies and methods are constantly being developed and applied. The main methods of aluminum plastic recycling include physical separation method and chemical separation method.

1.Physical separation method:

Mechanical sorting: Aluminum is separated from plastic by cutting, crushing and then using techniques such as rolling or electrostatic separation.

Flotation method: utilizing the characteristics of different densities to achieve the separation of aluminum and plastic in specific liquids.

2.Chemical separation method:

Solvent dissolution: Use chemical solvents that can dissolve plastic but not aluminum for separation, but this method may produce waste liquid that needs further harmless treatment.

Pyrolysis or catalytic cracking: Under certain conditions, aluminum-plastic composite materials are decomposed through high temperature, so that the plastic becomes oil and gas extractables, while the aluminum remains solid and can be recycled.

Because it is a mixture of two materials, if not separated then the value of recycling is greatly reduced. And the separation of aluminum and plastic does not require too high a cost and does not need to be so troublesome. Therefore, it is not recommended to use chemical separation method.

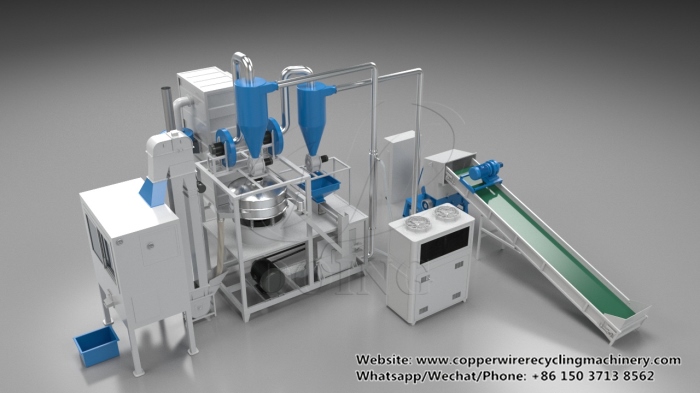

Aluminum-plastic separation machine

Aluminum-plastic separation machine

Doing Company aluminum-plastic separation recycling machine recycles and separates aluminum and plastic in aluminum-plastic composite materials based on the differences in physical properties of aluminum and plastic.

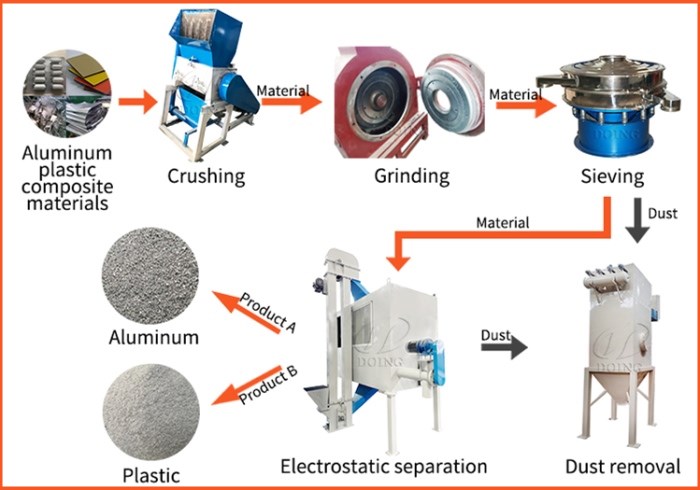

First, the aluminum-plastic composite material is sent to the crusher for crushing, and then ground into powder. The materials ground that meet the particle size requirements are separated by eddy-vibrating screen, finally the plastic and aluminum are separated by electrostatic separation equipment. Its process cost is low, efficiency is high, and the separation rate can reach 99.8%.

Working flow of aluminum-plastic separation machine

Working flow of aluminum-plastic separation machine

The whole process of aluminum plastic separation recycling machine is physical crushing and separation, without using water or chemicals, which is very environmentally friendly and pollution-free. And the whole process is fully automatic production line, saving labor, only one or two are enough to operate the machine.

Of course, the aluminum-plastic separation recycling machine mainly used for a variety of drug plates, aluminum and plastic plates, food packaging bags, milk bags, toothpaste skin, aluminum and plastic tubes, aluminum platinum paper, etc., the separation effect is obvious.

Doing Company aluminum-plastic separation recycling machine is tailored to help you accomplish this more efficiently and with minimal waste, enabling you to maximize your profits. If you are interested and would like to know more details, please feel free to reach out to us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

DOING Signs Contract with Ghana Client for 5-Ton Biochar Production Equipment

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

DOING 100-150kg/h circuit board recycling machine order in Zambia

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.