WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Is making charcoal energy efficient?

July 16, 2025

July 16, 2025- FAQ

- Leave a message

- Chat online

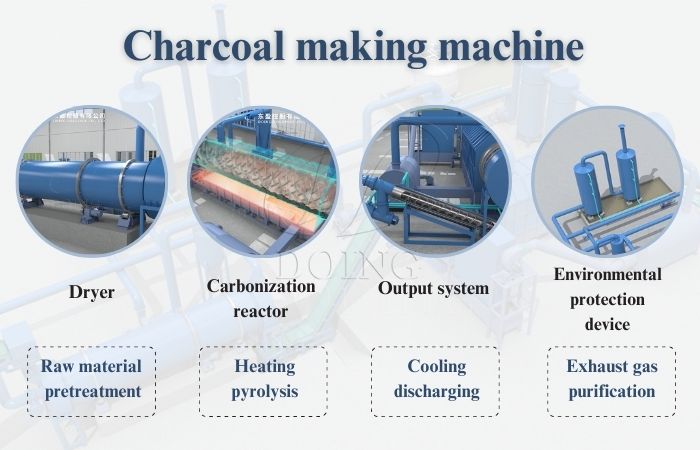

For a long time, the energy efficiency of charcoal production has been questioned because traditional methods waste heat and emit harmful gases. Fortunately, the new continuous carbonization machine solves the corresponding problems and provides a modern charcoal making solution that is both energy-saving and environmentally friendly.

Traditional charcoal production methods do have certain energy consumption, mainly reflected in raw material processing, carbonization process and equipment operation. Wood or biomass raw materials need to go through pre-treatment processes such as drying and cutting, which consume some energy. The carbonization process itself needs to maintain a certain temperature, and the traditional charcoal kiln method has a large heat loss and relatively low energy efficiency.

Traditional charcoal kiln

Traditional charcoal kiln

However, modern charcoal production technology has significantly improved this problem. Our continuous charcoal machines significantly outperform traditional methods, achieving substantial energy savings through intelligent design across three key areas:

1. Intelligent Raw Material Processing: Traditional methods over-consume energy drying high-moisture biomass. DOING machines feature an integrated pre-curshing and pre-drying system. Through pre-crushing, the biomass feedstocks for making charcoal will be shredded into small pieces that can be heated faster and more evenly, thus improving the efficiency of charcoal making. And the pre-dry raw materials can reduce energy for moisture evaporation and lower overall consumption.

2. Maximized Heat Utilization in Carbonization: Traditional methods suffer extensive heat loss. DOING charcoal making machines employ a fully sealed, high-efficiency carbonization pyrolysis reactor, minimizing thermal dissipation. Our core innovation is internal heat energy circulation: volatile gases are collected, purified, and re-combusted within the system. This maximizes fuel energy utilization, achieving significantly higher thermal conversion efficiency and reducing external fuel reliance.

Heat recovery and reuse system

Heat recovery and reuse system

3. Precise Energy Management through Intelligent Operation: Traditional operations suffer from imprecise control. DOING machines integrate an advanced PLC intelligent control system. This real-time monitors critical parameters and enables precise automated adjustments, ensuring optimal carbonization and peak energy efficiency, eliminating wasteful over- or under-processing.

DOING’s continuous charcoal making machines deliver unparalleled energy savings by optimizing raw material processing, optimizing the carbonization cycle, and implementing intelligent operational controls, offering a more economical, efficient, and environmentally friendly charcoal production solution.

Energy-saving charcoal making solution

Energy-saving charcoal making solution

When charcoal production adopts an energy-saving method, its environmental benefits are worthy of attention. The production of charcoal using agricultural and forestry waste as raw materials not only solves the problem of handling these biomass materials, but also converts them into valuable energy products. Compared with directly burning raw materials, charcoal has a higher energy density and a longer burning time, and relatively less pollutant emissions during use.

The charcoal production line developed by DOING company pays special attention to environmental performance. The exhaust gas treatment system can effectively reduce the emission of smoke, particulate matter and carbon dioxide during the carbonization process. The whole system is compactly designed and occupies a small area, which is suitable for charcoal production needs of different scales. In addition, by-products such as wood vinegar and tar can be recycled and used in agriculture and industry, further improving the overall energy utilization rate.

DOING continuous charcoal making machine

DOING continuous charcoal making machine

Whether charcoal production is energy efficient depends largely on the technology and equipment selection adopted. Through modern production methods and efficient equipment, it is entirely possible to achieve good energy utilization while ensuring the quality of charcoal. DOING is committed to providing customers with charcoal production solutions with excellent energy efficiency performance to help you succeed in this industry with development potential.

If you have any questions about the energy-saving potential of charcoal production or the performance of our continuous charcoal making machine, please feel free to contact us for consultation.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.