WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How much charcoal do I get from 1 kg of wood?

November 4, 2025

November 4, 2025- FAQ

- Leave a message

- Chat online

When producing charcoal from wood, one of the most common questions is: How much charcoal can I get from 1 kg of wood? The answer depends on several factors, including the type of wood, its moisture content, and the efficiency of the carbonization machine used.

1. Wood type: Different types of wood convert to charcoal at different rates. For example, hardwoods (like oak or eucalyptus) generally produce more charcoal than softwoods (like pine).

2. Wood moisture content: Wood with higher moisture content requires more energy to evaporate the moisture, so its charcoal yield may be slightly lower.

3. Carbonization machine and process: Different charcoal manufacturing machine and processes directly affect the efficiency and quality of charcoal production.

Under traditional methods such as earth kilns or brick kilns, the yield is typically low—only about 20–25%, meaning that 1 kg of wood produces around 200–250 grams of charcoal. These systems lose a large amount of heat energy and release significant smoke and emissions.

However, with modern carbonization systems, the yield can be improved substantially. Advanced biomass carbonization for charcoal making machine uses controlled oxygen-free conditions and PLC temperature monitoring to optimize the process. As a result, the charcoal yield can reach 30–35% depending on the wood type.

Modern high-yield biomass carbonization charcoal making machine

Modern high-yield biomass carbonization charcoal making machine

Therefore, using more efficient charcoal production machine increases the rate at which wood is converted into charcoal. Typically, 1 kg of wood, after high-temperature pyrolysis, can be converted into approximately 0.25 to 0.35 kg of charcoal. This ratio varies under different conditions.

In actual production, the wood-to-charcoal conversion rate depends not only on the equipment but also on the raw material handling and production environment. Professional charcoal making machine, such as the biomass carbonization machine provided by DOING, can significantly improve pyrolysis efficiency, helping you produce more high-quality charcoal with less wood:

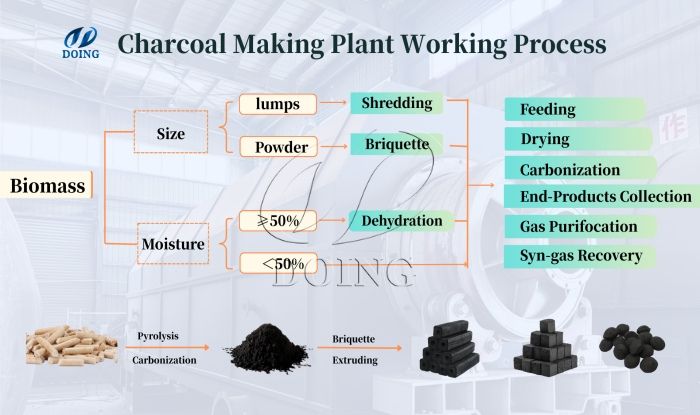

Before biomass raw materials enter the carbonization furnace, the DOING carbonization system crushes, granulates, and dries the materials, reducing their moisture content and achieving optimal carbonization.

DOING biomass carbonization pretreatment charcoal making process

DOING biomass carbonization pretreatment charcoal making process

Throughout the charcoal manufacturing process, the PLC intelligent control system assists users in monitoring and adjusting production conditions, reducing manual intervention and ensuring a more controllable conversion process, thereby improving charcoal yield.

The DOING modern charcoal manufacturing system also makes better use of byproducts. Wood vinegar and syngas produced during carbonization can be collected and reused for heating the carbonization furnace, reducing fuel consumption and improving overall efficiency.

Whether you are a startup entrepreneur just entering the charcoal industry or a producer with years of experience, choosing a high-efficiency charcoal making system is key to improving production efficiency. DOING's charcoal making machine has a good reputation in the market. If you want to maximize charcoal output while minimizing emissions, please consult the DOING carbonization charcoal production system – an effective and sustainable solution.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.