WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

Why is solar panel recycling crucial for India's sustainable energy future?

September 23, 2025

September 23, 2025- FAQ

- Leave a message

- Chat online

As India races toward its ambitious goal of 500 GW renewable energy capacity by 2030, solar panels are becoming ubiquitous on rooftops, farms, and industrial estates. However, this green transformation hides a challenge: what happens when these solar panels reach the end of their useful life? By 2030, India could generate more than 3 million tons of solar waste annually.

Faced with the challenges of waste and recycling, solar panel recycling is becoming a growing concern. Promoting solar panel recycling not only contributes to resource cyclical utilization but also builds a stronger foundation for India's sustainable energy future.

Why is solar panel recycling crucial?

1. Environmental Protection: Preventing Toxic Leakage

Solar panels contain heavy metals (lead and cadmium) and hazardous substances. Improper disposal can negatively impact the environment. Recycling effectively removes these hazardous substances from the solar panels, preventing them from entering soil and water sources and reducing damage to the ecosystem.

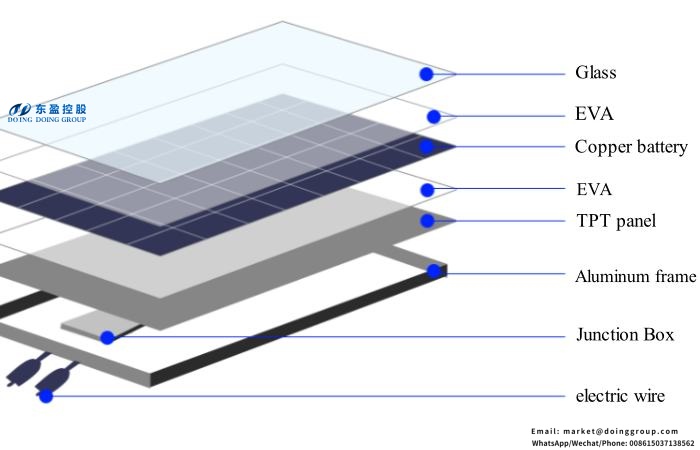

2. Resource Conservation: Recycling Precious Materials

A typical solar panel contains 75% glass, 10% aluminum, and 5% silicon. Recycling one ton of panels saves 1.2 tons of raw materials. With India's mineral imports increasing, this closes the resource loop. Therefore, Photovoltaic panel recycling not only reduces resource waste but also lowers the demand for new resources.

Recyclable solar panel material composition

Recyclable solar panel material composition

3. Promoting Economic Development: Turning Waste into Treasure

Through photovoltaic panel recycling, 95% of the materials (glass, aluminum, and silicon) can be safely reused. For example, recycled silicon can be used to manufacture new solar panels, reducing production costs. Glass can be used as a building material, and aluminum can be remelted for industrial uses. This will create more jobs in India and promote the development of a green economy.

India has made significant progress in solar energy adoption. According to recent news reports, by August of this year, India's installed solar capacity reached a new high of 123 gigawatts. The country has set a new goal: to establish a complete solar manufacturing ecosystem and achieve domestic solar cell production by 2028. Therefore, integrating solar panel recycling into energy infrastructure planning will help create a more complete and self-sufficient green energy ecosystem.

Solar panel recycling facilities for India sustainable energy development

Solar panel recycling facilities for India sustainable energy development

As the Indian government increases its support for renewable energy, the solar market will continue to expand. Developing corresponding solar panel recycling capacity is a natural and necessary link in the energy chain. Establishing a comprehensive solar panel recycling system will not only help protect the environment but also provide long-term support for India's energy transition.

As a professional manufacturer of solar panel recycling facilities, we offer advanced recycling equipment designed to provide efficient and environmentally friendly solutions for the Indian market. Our products not only meet international standards but also boast efficient resource recovery capabilities, enabling India to effectively process discarded solar panels and ensure maximum resource reuse.

DOING Solar Panel Recycling Machine Technical Advantages

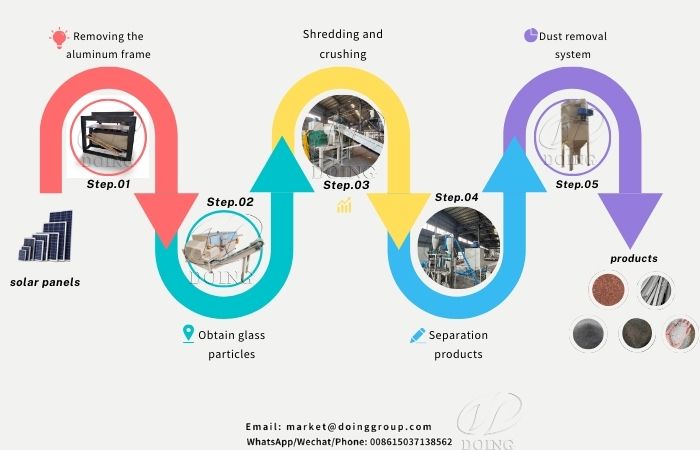

① Safely disassembles photovoltaic panels and separates materials such as glass, aluminum, and silicon from the solar panel cells.

② Purifies various materials to 98% purity for reuse.

③ Fully automated recycling lines minimize recycling costs through cost-effective processes.

Fully automated solar panel recycling production line

Fully automated solar panel recycling production line

④ A zero-landfill policy and flue gas treatment equipment ensure minimal environmental impact.

We understand the environmental and economic importance of solar panel recycling. Over 14 years of experience in the waste recycling industry, we have continuously innovated to promote sustainable energy development.

If you would like to learn more about our solar panel recycling facilities or require a customized solution for your business, please feel free to contact us. We look forward to working with you to advance solar panel recycling and contribute to India's sustainable energy future.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Lithium-Ion Batteries Recycling Industry: Current Status and Future Prospects Review

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.