WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How is wood charcoal prepared?

August 28, 2025

August 28, 2025- Industry News

- Leave a message

- Chat online

Wood charcoal preparation is the process of converting wood into a highly efficient fuel through appropriate methods. Traditionally, wood was carbonized in earthen kilns or pits, an inefficient and environmentally harmful process. Modern charcoal production combines traditional knowledge with modern technology to ensure wood charcoal quality while prioritizing environmental protection and resource utilization, providing a faster, cleaner, and more efficient solution. Here's how it works:

Basic Principles of Wood Charcoal Preparation

The core principle of wood charcoal preparation is high-temperature pyrolysis. In this process, wood or biomass is heated in an oxygen-deficient environment, gradually breaking down volatile compounds and leaving behind a carbon-rich solid residue known as charcoal. This method helps retain the energy density of wood while reducing smoke production, resulting in a cleaner burn and higher calorific value than raw wood.

Basic principles of wood charcoal preparation: biomass pyrolysis

Basic principles of wood charcoal preparation: biomass pyrolysis

Key Steps in Wood Charcoal Preparation

1. Raw Material Selection and Preparation

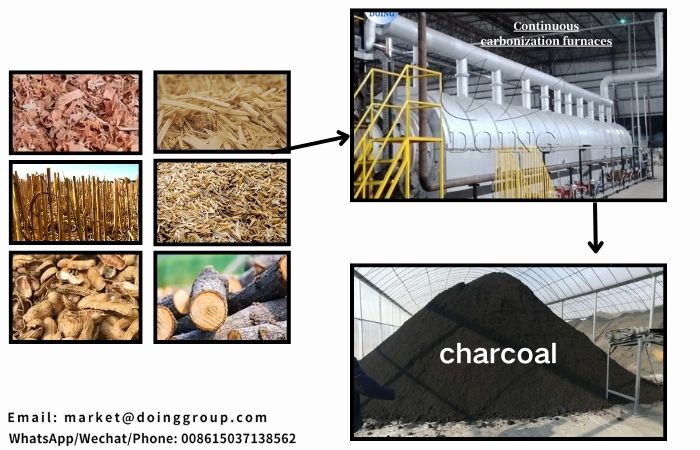

The first step in wood charcoal preparation is selecting the right raw material. Hardwoods, such as oak, beech, or walnut, are widely used due to their high density and carbon content. Other biomass raw materials can also be used for charcoal preparation: such as bamboo, wood chips, sawdust, fallen leaves and other forest waste, coconut shells, palm kernel shells, nut shells and other agricultural waste. Before carbonization, the wood undergoes pre-treatment, such as crushing and drying, to remove excess moisture and uniformize the wood size for easier handling.

2. Carbonization Process

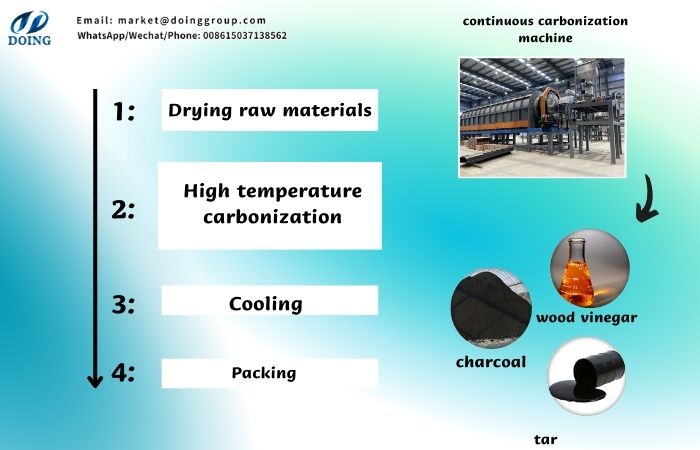

Charcoalization is a critical step in wood charcoal preparation. Dried wood is fed into a carbonization furnace or reactor, where it undergoes pyrolysis under oxygen-deficient (oxygen-limited) and high-temperature conditions. The temperature is typically controlled within a specific range, with the wood typically heated to high temperatures (400-600°C) to ensure the decomposition of organic matter while avoiding over-combustion. This thermal decomposition drives off volatile substances and gases, leaving behind solid charcoal and producing recyclable by-products such as wood vinegar and wood tar.

Carbonization process for wood charcoal preparation

Carbonization process for wood charcoal preparation

3. Cooling and Collection

After carbonization, the resulting wood charcoal is typically extremely hot and requires forced cooling to reduce its temperature, prevent spontaneous combustion upon contact with air, and maintain the quality and structure of the charcoal. The cooled wood charcoal is collected and screened to remove debris and incompletely carbonized portions, ensuring the quality of the final product. The final charcoal product is packaged according to its intended use (barbecue, industrial, agricultural, or as activated carbon) and stored in a dry environment to prevent moisture absorption and compromise its combustion properties.

4. Charcoal Pressing (Optional)

Products with specialized wood charcoal shape requirements can press the resulting charcoal powder into shapes. Common charcoal forms include bars, blocks, and pellets. After mixing the prepared charcoal with a binder, a charcoal press briquetting machine uses mechanical pressure to press the charcoal powder into the desired shape, improving its density, hardness, and uniform appearance. This process not only improves the charcoal's physical properties but also enables precise mold control to produce a variety of charcoal forms that meet market demands.

Charcoal press briquetting machine for different charcoal shapes

Charcoal press briquetting machine for different charcoal shapes

Through the above charcoal preparation process, we can obtain high quality charcoal for sale or other wide applications, such as metallurgy, barbecue fuel, soil improvement and activated carbon production. With technological advancements and increasing environmental protection requirements, modern charcoal preparation methods prioritize efficiency and environmental friendliness. Professional carbonization machine allows for better control of carbonization temperature, time, and an oxygen-free environment, thereby increasing charcoal yields. Furthermore, byproducts can be recycled, achieving a resource-efficient process.

Modern charcoal preparation methods and steps

Modern charcoal preparation methods and steps

Modern charcoal-making machines are equipped with fume purification systems that process and recycle generated gases, converting them into heat for reuse and reducing pollutant emissions, making the entire process environmentally friendly and energy-efficient.

As a manufacturer of charcoal making machine, DOING offers a wide range of charcoal production line models to help users optimize their charcoal preparation processes. Our equipment is designed for practicality and stability, making it suitable not only for small- and medium-scale production but also for large-scale charcoal production. If you are interested in charcoal preparation machine, please contact us for more information. We will provide professional advice based on your needs and recommend the most suitable equipment model.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 1000kg/h Solar PV Panel Recycling Machine Shipped to India

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.