WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

The DOING Straw Continuous Charcoal Making Machine Process Principle and Process

November 18, 2025

November 18, 2025- Industry News

- Leave a message

- Chat online

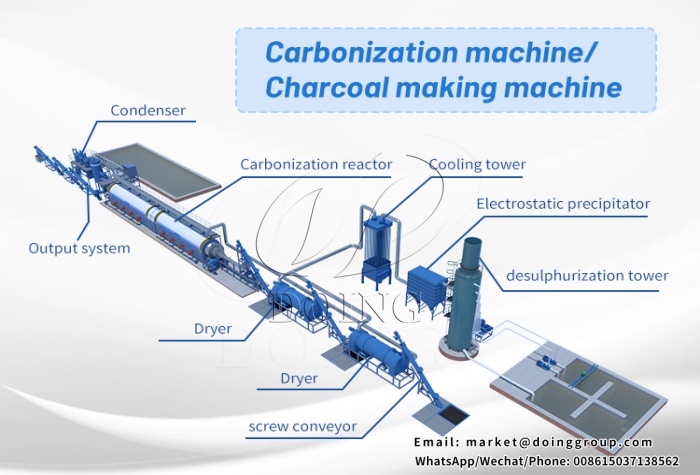

The DOING straw continuous charcoal making machine is a device used to convert biomass feedstocks such as straw into biochar. Its process is based on pyrolysis carbonization technology. By heating straw at high temperatures in the absence of or oxygen, it undergoes a thermal decomposition reaction, ultimately producing products such as straw charcoal, combustible gas, and wood tar. The following is a detailed description of its core process principles and process:

Straw continuous charcoal making machine

Straw continuous charcoal making machine

The DOING Straw Continuous Charcoal Making Machine Process Principle

Pyrolysis carbonization refers to the decomposition of biomass such as straw by heating in the absence of or oxygen. Products include gases (combustible gas), liquids (wood vinegar, tar), and solids (coke). This process consists of three steps: pyrolysis, carbonization, and cooling. Pyrolysis involves heating the straw to high temperatures, burning off moisture and organic matter, leaving behind carbon and hydrocarbons. Carbonization involves further heating the remaining carbon and hydrocarbons to form a stable carbon structure. Cooling involves cooling the newly formed char to room temperature, allowing it to solidify into its final form.

Working Process of the DOING Continuous Straw Charcoal Making Machine

Pretreatment

Straw is collected and processed into pellets smaller than 20mm using a pulverizer to ensure uniform heating and flow within the charcoal making machine. A drum dryer is used to reduce the moisture content of the straw to below 15% to prevent high moisture content from reducing pyrolysis efficiency and affecting carbonization results.

Pyrolysis Carbonization

The pretreated straw is conveyed via a conveyor belt into the main charcoal making machine for carbonization. The pyrolysis furnace is heated by an external heat source, such as a oil burner, and the straw carbonizes within the furnace. When heated to a certain temperature, combustible gas begins to be generated. Once combustible gas is generated, the burner can be gradually shut down, and only the combustible gas generated during straw carbonization is used for heating. Note that if the straw pyrolysis combustible gas is insufficient, additional external heat source may be required.

Straw pyrolysis carbonization system

Straw pyrolysis carbonization system

Cooling and Charcoaling

The pyrolysis-carbonized straw charcoal is fully cooled through a water-cooling circulation system before being transported to the material yard or silo for packaging or storage. The cooling water in the cooling system is cooled in a cooling tower and then recycled through a water pump.

Charcoal Processing(Optional)

Generally, the resulting straw charcoal can be used directly for basic purposes such as combustion, soil improvement, or as an adsorbent. However, if you have higher requirements for the appearance of the finished straw charcoal, you can use DOING's matching briquetting extrusion equipment to shape the charcoal into spherical, rod-shaped, or block-shaped straw charcoal. This not only improves the regularity and aesthetics of the product but also facilitates packaging, transportation, and storage. It also meets the refined morphological requirements of specific applications (such as barbecue charcoal, metallurgical reducing agents, or raw materials for handicrafts).

Charcoal making machine with briquettes extruder equipment

Charcoal making machine with briquettes extruder equipment

Flue Gas Recovery and Reuse

The flue gas generated during carbonization is purified and separated by a Shaker, then returned to the combustion chamber by an induced draft fan for secondary combustion, further heating the main charcoal making machine. Combustion gas replaces external fuel for heating, achieving self-sustaining heat. Furthermore, the waste heat from heating the main furnace is simply removed by a dust removal device and then introduced into the drying furnace to dry the material, forming a closed energy loop.

Exhaust Gas Purification and Emission

This includes two types of exhaust gas: the exhaust gas generated after drying is first dedusted by a Shaker and then purified in a spray tower; the exhaust gas directly generated by the combustion chamber is first cooled by a tube cooler and then purified in a spray tower. Finally, both exhaust gases are discharged into a chimney.

DOING continuous biomass charcoal making machine

DOING continuous biomass charcoal making machine

The DOING continuous straw charcoal making machine thus represents a complete, environmentally-sound solution for biomass conversion. By integrating pyrolysis technology with efficient heat recovery and gas purification systems, it achieves energy self-sufficiency while minimizing emissions. This closed-loop design not only ensures optimal carbonization efficiency but also sets a new standard for sustainable agricultural waste management through its circular economy approach.

The DOING continuous straw charcoal making machine, with its high efficiency and environmentally friendly features, is an ideal choice for comprehensive straw utilization. In addition to straw, our charcoal making machine is also suitable for the treatment and recovery of agricultural biomass waste such as rice husk, coconut shell, bamboo, palm shell and wood chips, helping to build sustainable carbon neutral projects.For more detailed equipment specifications, please contact DOING. Our professional team of engineers and experienced business managers provide one-on-one service to help achieve a green transformation of agricultural waste.

Contact Us

- Email:

- Tel/WhatsApp:

News

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Process Workflow and Equipment for Lithium Battery Recycling

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.