WhatsApp

WhatsApp

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

E waste recycling machine manufacturer

- WhatsApp: +86 150 3713 8562

- Email: market@doinggroup.com

How to properly dispose of mobile phone batteries?

August 29, 2024

August 29, 2024- FAQ

- Leave a message

- Chat online

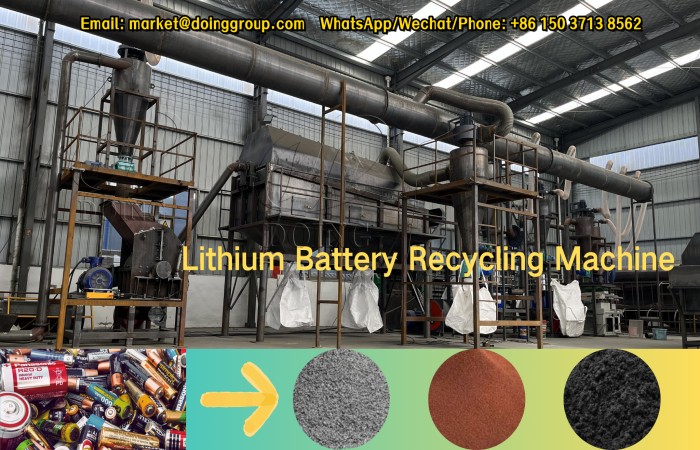

DOING lithium battery recycling equipment is designed for disposal of mobile phone batteries and other similar batteries. Lithium battery recycling equipment can separate copper, aluminum, graphite (black mass) and diaphragm from waste batteries.

Lithium-ion batteries power the vast majority of modern smartphones due to their high energy density, lightweight and rechargeability. However, these same properties also make them potentially hazardous when not handled or recycled appropriately. We need a proper disposal way to manage these waste mobile phone lithium-ion batteries.

The Importance of Lithium Battery Recycling

The waste mobile phone batteries, namely lithium-ion batteries, contain heavy metals and toxic chemicals that can contaminate soil and groundwater if disposed of in landfills or incinerated. Moreover, they pose a fire risk due to their reactive nature, especially when damaged or improperly stored. Thus, specialized recycling processes and lithium battery recycling machines are necessary to ensure safe handling and material recovery.

Lithium battery recycling equipment

Lithium battery recycling equipment

Recycling waste mobile phone lithium batteries not only mitigates environmental risks but also recovers valuable materials like lithium, cobalt, nickel, and copper, which can be reused in the production of new batteries and bring new profit return.

Waste Mobile Phone Lithium Battery Recycling Equipment and Processes

The recycling of waste mobile phone lithium-ion batteries involves several stages, each requiring specific equipment designed to handle the unique challenges of these energy-dense power sources.

1. Collection and Sorting

The first step in the recycling process is the collection of used mobile phone batteries. This can be done through designated collection points, take-back programs offered by manufacturers or retailers, or municipal waste management systems. Once collected, batteries are sorted based on their chemistry (lithium-ion, lead-acid, etc.) and condition to optimize the recycling process.

Lithium battery recycling equipment

Lithium battery recycling equipment

DOING has over fourteen years of professional experience in waste recycling machinery, and has a high-quality engineer team, which is committed to providing first-class solutions. DOING lithium battery recycling and processing technology adopts mechanical and physical separation methods, that is, copper, aluminum, diaphragm and black powder are obtained through shredding, crushing, pulverizing, screening and sorting processes of waste lithium battery recycling equipment.

2. Pre-Treatment and Disassembly

To safely recycle waste mobile phone lithium-ion batteries, they must first be discharged to reduce the risk of fires or explosions during processing. This is followed by disassembling the battery packs into their constituent parts: the casing, electronic circuits, and individual cells.

Lithium battery recycling equipment

Lithium battery recycling equipment

Equipment used:

Discharge: Soak mobile phone waste lithium batteries in 8%-15% NaCl solution for 48 hours to fully discharge the batteries. Compared with other methods such as physical discharge or fire discharge, wet technology is favored due to its high efficiency and practicality.

Mechanical disassembly system: Use advanced technology shredder to efficiently shred lithium batteries to achieve the separation of lithium battery diaphragm, positive and negative plates, and shell.

3. Carbonization

The shredded materials are conveyed into the carbonization stove. During the carbonization process, the electrolyte and adhesive are pyrolyzed and gasified. The tail gas after carbonization is treated multiple times to meet the emission standards and avoid environmental pollution.

4. Cell Crushing and Separation

After screening, the black powder is sorted out; the remaining materials are further crushed and separated, and copper and aluminum are sorted out by high-precision sorting machines.

Lithium battery recycling equipment

Lithium battery recycling equipment

Equipment Used:

Crushing: Includes crushers and grinders to break materials into sizes that are easy to sort.

Separation: Including rotary screen, air separator, magnetic separator, eddy-vibrating screen, etc. to separate different products (diaphragm, copper, aluminum and a small amount of black powder, etc.).

Environmental and Economic Benefits

By recycling waste mobile phone lithium batteries and other similar batteries, we reduce the need for raw material mining and save natural resources. In addition, recycling consumes less energy than raw material mining and processing, thereby reducing greenhouse gas emissions. These screened materials such as copper powder, aluminum powder and black powder have a wide range of application value in many fields and can bring good profits.

After the above process, the valuable components in the waste mobile phone lithium batteries are effectively recovered, and the separation effect can reach more than 98%. If you need more details about the waste mobile phone battery disposal way and lithium battery recycling equipment, please contact us.

Contact Us

- Email:

- Tel/WhatsApp:

News

Indian customer ordered DOING 100-150kg/h circuit board recycling machine

DOING 100-150kg/h PCB Recycling Machine Shipped to Zambia, Powering Local E-Waste Automation

DOING 5-ton/hour biomass carbonization machine shipped to Ghana

Indian customer ordered DOING high-recovery-rate 1000 kg/h photovoltaic panel recycling machine

Contact Us

If you want to get more details, you can send E-mail to market@doinggroup.com. Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP.